WHERE INDIVIDUALITY IS THE RULE

Manufacturers of cutting and precision tools seeking to maintain their competitiveness over the long term must show flexibility – and all the more so if they do not manufacture tools directly, but on a (sub)contract basis. Usually, there is no such thing as »the one and only standard tool«. Therefore, your customers expect user-oriented product ideas and individual solutions. Short response times and topnotch quality are key success factors in the industrial arena, and so are process security and efficiency. Such comprehensive requirements can only be met with equally comprehensive know-how, mature technology and reliable quality control. Schneider Messtechnik will provide you with the reliability you need, by supplying precision and practice-oriented hightech solutions that will place you a cut above your competition.

Far from ordinary – close to the pulse of the market

Whether it’s twist drills, reaming tools, countersinking tools, milling tools, broaching tools, gear cutting tools, threading and turning tools, saw blades, cutting plates, you name it: The range of cutting and precision tools is immense, and so is the variety of industries who use them. Each new order reflecting specific customer requirements brings new tasks and fresh challenges to your business – an aspect which we at Schneider never lose sight of. We keep a steady forward-looking eye on your success in the tool manufacturing arena by planning, designing and manufacturing measuring instruments which proactively take account of all conceivable requirements. It thus comes as no surprise that our measuring machines are fit for any industrial application.

Precision from A to Z

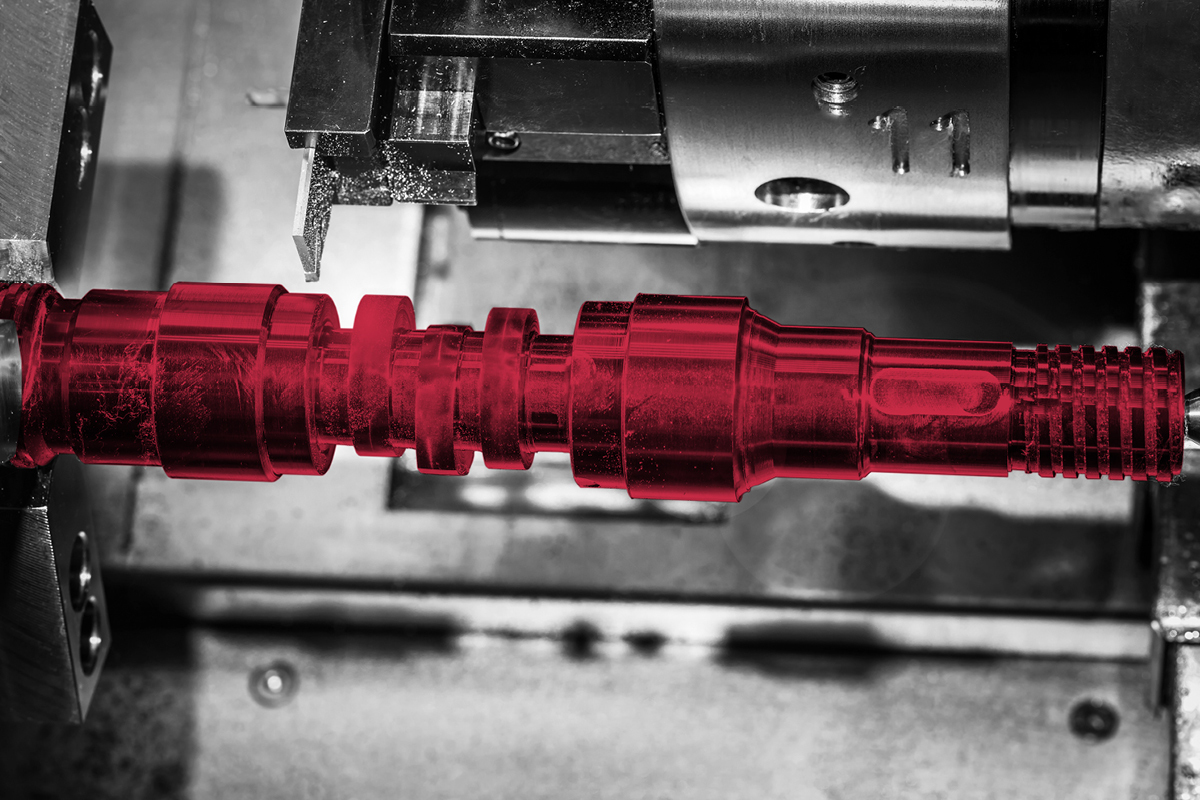

Our WMM 3D multisensor shaft and turned part machines allow a wide range of lengths, diameters, radii, angles and chamfers as well as rotationally symmetrical parts in just one work step – and that at a speed that significantly reduces your throughput times. Our PMS Series of compact granite construction is no less impressive: With high-resolution CCD cameras, tactile switching or scanning probes and optional laser sensor, these machines are also ideal for universal industrial application, and hence close to the demands of the market.

A new dimension in tool measurement

Sophisticated high-tech features and brilliant optical measurement make the STP 500 universal tool presetting fixture a pioneering innovation in tool measurement. No matter whether in the production or regrinding of drilling and milling tools or even of highly complex cutting machines or blades: The STP 500 offers you everything you need for continuous quality control and assurance and provides selective support for the control of your other production processes. Tough, manoueverable when it counts and well planned down to the last detail, it is highly precise, ergonomical und uncompromisingly cost-effective in every application.